Audit

What is the real potential of your facility?

What is the real potential of your facility?

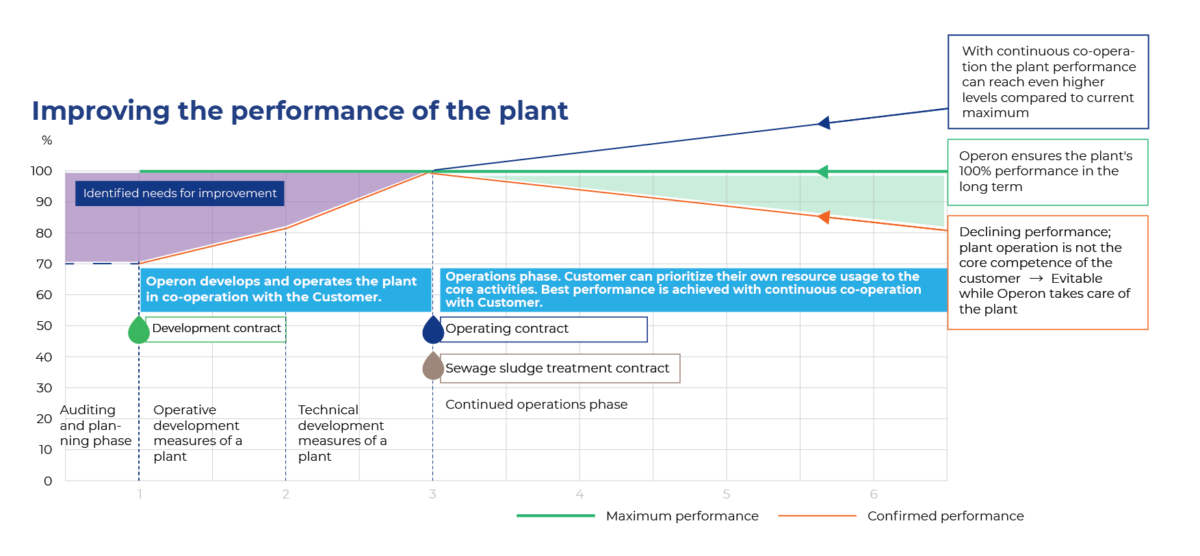

The audit concept launched by Operon is a way to identify the service components your facility will need to improve its performance. Auditing is used to identify and illustrate the technical and financial performance of the water treatment facility in a clear and understandable manner.

Potential development measures are determined on the basis of present-day data, and they are used to improve the efficiency of the plant.

The effects of the developmental measures are compared to the where the facility is right now, both technically and financially. As an outcome of the audit, you receive a clear road map, and its priorities can be set on the basis of your preferences.

When plant performance or efficiency is not meeting the requirements, it is crucial to find out what can be done. Operon determines alternative ways to renovate the plant. Typically there are multiple different approaches and alternatives to do this.

There are many different operations related to water around the water utilities. It is difficult to get the overview of the situation, and multiple ways to proceed makes the comparison even more difficult. In Operon Audit we map out a clear picture of current state, and innovate different development paths to be taken in use for the needs of water utilities and water systems.

Plant renovation on a planning phase, but the required scope is not yet clear. Is the plant’s current state really meeting the current maximal capacity? What could be the most efficient way to ensure cost efficient renovation project?

Employees in the plant have changed, and it should be found out how the plant should be operated, and how the competences and resources are secured for the future. Operon Audit clarifies different ways to succeed in the future.

Operon audit process ensures that the plant is developed as cost efficiently and sustainbly as possible.

Audit service ensures an efficient development of the plant in the future, and offers immediately tools and alternatives to develop operations.

2016 Audit – Industrial WWTP / Food industry Finland

2017 Audit – Industrial WWTP / Food industry Finland

2017 Audit – Industrial WWTP / Chemical industry Finland

2017 Audit – Industrial WWTP / Chemical industry Finland

2017 Audit – Industrial WWTP / Chemical industry Finland

2017 Audit – Industrial WWTP / Chemical industry The Netherlands

2018 Audit – Industrial WWTP / Food industry Finland

2018 Audit – Industrial WWTP / Aluminium industry The Netherlands

2018 Audit – Municipal and industrial WWTP / Food industry Denmark

2018 Audit – Industrial WWTP / Food industry Sweden

2021 Audit – Municipal WWTP 5 plants Finland

2022 Audit – Industrial WWTP + Upstream processes + Sewer network / Food industry Finland

2022 Audit – Municipal sewer network + WWTP Finland

2022 Audit – Industrial WWTP / Drinks and beverages industry Finland

2022 Audit – Industrial WWTP / Sludge treatment / Food industry Finland

2023 Audit – Municipal WWTP + Sewer network Finland